Our buddy Robin Walters, AKA Doc Wobbles, has a really cool company over in the UK selling Ti bolts and other trick shit right here and he also build this bike from the ground up for a customer, the last real works bike! Incredible job and in his words, here’s how he did it.- Steve

There is always a lots of speculation around what is the best bike of all time. It’s a very personal thing – and there are a lot of factors you need to take into consideration when thinking “what is the trickest”? For most of us, it’s a bike we used to own or lust after, the rider or the brand you associate with– but you wouldn’t be too far wrong throwing your hat in the ring with the 1986 Honda RC 500 for the title.

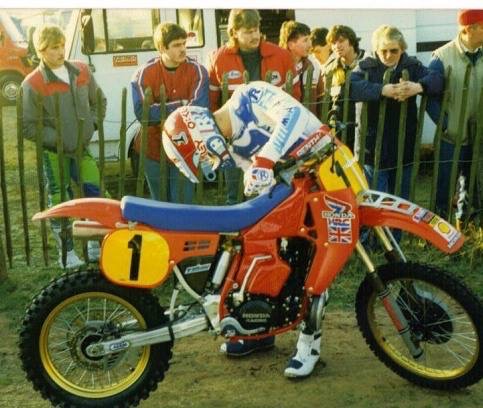

This actual bike won the 1986 FIM World 500 championship as part of the mighty Honda HRC factory effort. A time when the bikes were full factory, not the watered down production-based bikes we’ve grown to accept as the pinnacle. – No, this was one of the last full factory bikes where very little from a production bike comes close and the forefront of the development for the MX world.

For me the only bike that comes close to this Honda is the Yamaha YZM 500 from 1987 and 1988. Afterall, Yamaha never made a production watercooled 500, so that in itself was pretty cool. Add to the fact it had an aluminium frame, a version of which wouldn’t be seen in production for 18 years (that’s like the factory guys getting something we wouldn’t be able to buy intill 2039!). However the yardstick of the bike has to be measured in success and I don’t think the YZM ever won a race as trick as it was. Add to the fact I know that the monocoque subframe / airbox would crack each time it was ridden (the mechanics had 6 of these in circulation at the welders at all times) and it’s a very cool bike but winning a World Championship at a time when the competition was at it’s height, was no meager feat. And Dave Thorpe, the pilot of this RC500, did it three times.

Dave Thorpe is an icon in the UK and World MX scene in the 80’s and 90’s. The man is an absolute legend and gentleman. Though MXA famously dubbed him the fastest amateur, to us here in the UK, he was god-like. Anyone who attended any of the Grand prix events in those glory years will confirm, it was a very special time indeed.

Ask what the greatest race they’ve ever seen and its not long until someone says “Thorpe Farleigh Castle”. I was there that day and the crowds were incredible. I’ve never seen so many people at a MX event. The infield was full from track-side to track-side, ten deep on the outside of the circuit and add that t it was hot! Not just by England standards but proper warm, you could tell where DT was on the track by the Mexican wave of fans all cheering him on.

On the start of the 2nd moto of the day (both 40 minutes plus 2 laps), it was normal for the races to be nearly 50 minutes long. Pumped up by the crowds the British riders were all up for it. From the start, someone hit Mervyn Anstie from the back (Max’s dad) and he in turn hit Thorpe clean off the track into the crowd. In the next 10 or 15 minutes DT picked himself up and set off after the pack, passing guys on the inside and outside– it was a sight to behold and the greatest comeback anybody there ever witnessed! I was standing behind Keith (Dave’s father and mechanic), watching the events unfold. At that point I decided my career path. I was done as a rider and I was going to be a GP mechanic…. one day.

Still to this day only 2 people ever make me nervous when my phone rings with their name, Mitch Payton and Dave Thorpe! Only from the immense respect I have for these guys.

So to get to the point, the bike in question….For years, a rider would have it in his contract, should he win a Championship, they get to keep the winning bike as a trophy, a souvenir and a thank you from the manufacturer. Honda used to honor this deal but they would instruct the mechanic to build the bike after the final race but leave out any of the internals from the suspension or motor, should the rider leave the team or worse another manufacturer get hold of the technology. After all, this was cutting edge, not over the counter production based bikes. So Thorpe ended up with his 1985, 1986 and 1989 Factory HRC RC500’s.

Fast forward 25 years and my heart skips a beat as my cell phone rings, its Dave Thorpe on the end of the line asking if I know anyone who wants to buy his championship bikes?! My first thought was he’s lost it-who in their right mind would sell such an icon, a symbol of your achievements?!

He went on to explain that he has to insure them every year. People ask to borrow one here and there for shows or dealer openings (we borrowed his ’86 for the Dirt bike show here in the UK when I was the founding editor for MOTO magazine), he didn’t want the bikes in his house and storing them was proving to be a challenge as these bikes are not built to look good but to be brutally effective. The bike is only ever in one piece for one weekend of their very short lives and they don’t look pretty and shiny for long. Nothing is anodized or coated to prevent corrosion and the simple fact is they don’t look good for long.

The UK at the time was starting to become bad for bike thefts and with 3 bikes so valuable, it was a security concern. The concerns were cemented when somebody tried to break in and take one.

Add to the fact you have to try to think like the rider, these bikes are just a tool to get the job done. For the rest of us mere mortals, we believe if we had that bike we would conquer the world but in reality it’s the hard work, dedication and skill of the pilot that wins; not the bike. That is merely a tool to get the job done. It’s like Usain Bolt thanking his shoes, Mike Tyson thinking his gloves knocked out his opponent or without a certain ball, Michael Jordan wouldn’t be great. These guys are at the top of their game for their effort–not the tool that facilitates greatness, and I get that.

The bike is fucking trick though.

So the bikes all got bought by 3 different collectors. The 85 ended up in South Africa, the 86 was bought by the collector we did the work for and the 89 was bought initially by a UK collector who sold it into Germany and it’s now in the USA, I believe. At the time they seemed expensive but in reality they were a snip compared to their value now.

I’ve imported a few bikes for the collector who owns the 86, which in most peoples eyes the trickest of the three. It is the last of the “full works bikes”, if you like. Though Honda, in 86, had a watercooled CR 500 with Pro Link suspension and a disc front brake, that’s where the similarity’s end. Only the handlebars, tires and front fender is common between the two bikes. They were as worlds apart as they could possibly be. The owner approached me with his desire to get the bike re-commissioned back to its former glory. He wanted to not only start the bike up but have it fully functional as it was the day it won the championship in 1986, a tall order indeed.

Now I cant take any credit for the bike itself. I simply took it apart, cleaned it and put it back together. Sure there was the task of locating the missing parts but it’s a stretch to say I restored it. The bike was factory exotica before I started, just a little jaded and looking sorry for itself.

First job was to strip it and see what we were dealing with. Get a wish list of parts we would scour the globe for and anything we couldn’t find, we would have to make (luckily that wasn’t the case in the end). The bike came apart easily, nothing seized up which in itself was impressive. The engineering under the skin was starting to show its pedigree and by the end of day one I had lots to find.

The suspension, well more accurately, the forks, were a drama. The suspension internals were found in Belgium and France I believe, (sometimes its best not to ask) the biggest stress was the lower fork tube had cracked where the axle mounts. Now these are cast magnesium so they cannot be welded. The same guy who had the fork internals also by chance had a fork leg. The only problem was it was an entirely different color. Quite often the cast magnesium parts were not matching color-wise but this was too far away to make a pair.

So we stripped both forks down and with the spare lower leg we got them blasted back to the same color and finish. I know a magnesium plating company who do a lot of work on mag classic road race parts, so we got them re-plated and they were similar–we were now in business. A rebuild with all new oil and seals (not easy to find as well as the bushings) and the forks were ready.

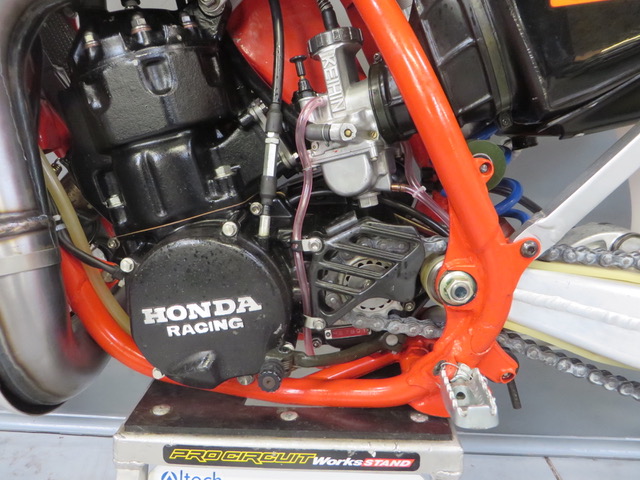

The motor was a big job. The owner used lots of his pull and found parts for this in Holland, Belgium and Germany and it was simple enough to rebuild. The weighted, balanced crank is a work of art. The rest of the clutch and transmission have quite a production look in fairness but you have to remind yourself this is a 30 year old bike and things have come along since this bike was built. The only part we struggled with was the electrics. We had the HRC coil attached to the bike, the stator was also in place but matching it with a flywheel wasn’t easy. Then the ecu had a completely different quantity of wires and nothing matched color-wise. In the absence of a wiring diagram it was a case of removing all of the plugs and it was trial and error. In the end, I have to give props to one of my mechanics, Mikey. He persevered with it after I had thrown in the towel, I couldn’t get a spark after 3 days messing with it and had given up. Ready to call the owner and tell him it was built but wouldn’t start, he managed to do a combination and it sparked! In the end it fired up 3rd kick and sounded mint! It was a lot of work re-soldering all of the HRC connectors but it was worth it in the end.

The chassis was an eye opener. The swingarm is a work of art, with nothing having a rear disc in production as yet it was all factory and very cool. The rear axle actually was tapered. It had bigger bearings on the sprocket side and believe it or not there was a needle roller in there not a regular bearing–I’ve never seen that before or since.

The wheel spacers have a shoulder that goes inside the bearing, this stops the spacer from falling out during wheel changes. The aluminum spacers have an insert with bearing steel. All super trick and almost unnecessary but really cool. Even the rear sprocket has a bigger internal diameter than the standard CR/CRF fitment has been for years. Keeping the same bolt pattern–no idea why they changed that.

The cooling system is impressive in itself. The bike has a small radiator on the left side as you sit on it, however the right side has a huge radiator that is kinked halfway down. The factory were already working at getting the center of gravity as low as they could–this thing is incredible and I’ve never seen anything like it! I dread to think of the cost.

The tank is also something else. They had the fuel so low in the bike it couldn’t gravity feed the carb as per every other bike, they had a small vacuum pump in the lowest part of the tank with a pulse tube to operate it from the side of the transfer port on the cylinder. This pumped the fuel up to the tap–again, this has never made it to production on any bike I’ve ever seen.

The low slung tank has the recess for the kickstart, proper factory.

The bike was not easy to re-assemble after re-greasing. With most bikes you get for example, a shock bolt or link bolt somewhere near and with a wiggle and a little pressure the bolt slides through–not on this bike. It’s a 2 man job. There is simply such minimal level of tolerance you have to line everything up 100% perfectly before the bolts would go through and when they tightened, it was a really positive feel. Not like everything is getting pulled together more like its snugly tight– weird but ever so trick.

The bike over its time has a bunch of the titanium fasteners missing and replaced with nasty steel mis-matching bolts. Luckily we manufacture our own line of titanium bolts we supply to many factory MX teams worldwide. On the bike there was over 100 bolts we needed to replace. Now it’s fully titanium and aluminum fasteners throughout.

The pipe is ever so cool but it was pretty pitted with rust behind the aluminum pipe guard. We got this finished and buffed, then the welds re-blued to look new.

The graphics were in good shape. We just had to take the AFAM one from the swingarm so it could be buffed to the brushed finish. Nothing too shiny as per the original spec.

The bike is now back in the private collection, ready for action. We were working towards having a magazine test and photo shoot but I think the owner got nervous about letting it out on track. After all it’s worth the same price as a 3 bedroom house and if the rider has an off and wrecks a rad or subframe, it’s all over….

In the end we got to rebuild one of the most iconic bikes ever built and check out some of the engineering that went towards HRC winning ways.

Cool HUH.